Manual Book of Advanced Belt Type Onion Peeling Machine

The company’s research and development of RM-OP1 type onion peeling machine, is the current domestic and foreign advanced production of onion processing equipment, the machine has won national patent. The equipment consists of the following parts:

1. Charging device:

The feeding device adopts a stainless steel conveyor belt, an automatic feeding machine and a continuous flow conveying onion. The utility model has the advantages of simple design and convenient operation.

2. Gash skin device:

The gash skin at the top of the device, the surface of the first, second layer to gash the skin of onion.

3. Skin blowing device:

The skin blowing device is mainly composed of a high pressure nozzle and a high-speed rotating support roller. After gash skin of onion to the high-speed rotation of the roller, and the high pressure jet, the first, second layer of skin from the onion.

4. Finished onion conveying device

The peeled onion slides onto the dragon and is delivered to the designated position.

5. Waste conveying device:

Waste through the auger leak into the bottom of the rubber belt conveyor, to waste in a box.

Usage

1、Install:Put the 4 bolts at the bottom of the equipment and fully adhere to the floor and the ground.

2、Coherent:Connect the air outlet of the air compressor to the intake (as shown in Figure 1),and the air pump pressure is ≥1.0Mpa;

3, Wiring::

connect the power line (three-phase four wire) to the input terminal of the electrical box; close the breaker; the “power indicator” lights up and the touch screen lights up;

- If touch screen alarm:“Phase sequence error!”, indicating that the power line phase sequence error, please power off any two-phase line of fire.

- If the touch screen alarm:“Inverter of converyor fault!”, note that there is a fault in the transmission motor. Please refer to the inverter manual to find the problem and eliminate the cause of the fault.

- If the touch screen alarm:“Inverter of peel motor fault!”, note that there is a malfunction of the peeling motor inverter. Please refer to the inverter manual to find the problem and eliminate the cause of the fault.

- After any of the above failures occur, after removing the cause of the fault, press the “Alarm page” on the touch screen “Reset” after the lifting of the fault alarm, in order to normal operation again.

- If you can not lift the alarm, please contact the company aftermarket.

Press the “Start” button, the indicator light is on, the device is powered on, then start the “automatic mode” equipment to start normal operation;

Press the “start” or press the “emergency stop” button, the indicator light off, the device work power is off, pay attention if you do not stop the “Auto Mode” of the touch screen, when you reset the “Emergency Stop” button, or press “Start” again, the device will continue to run;

Press the “emergency stop” button at any time, the device power supply immediately disconnects, the device stops running.;

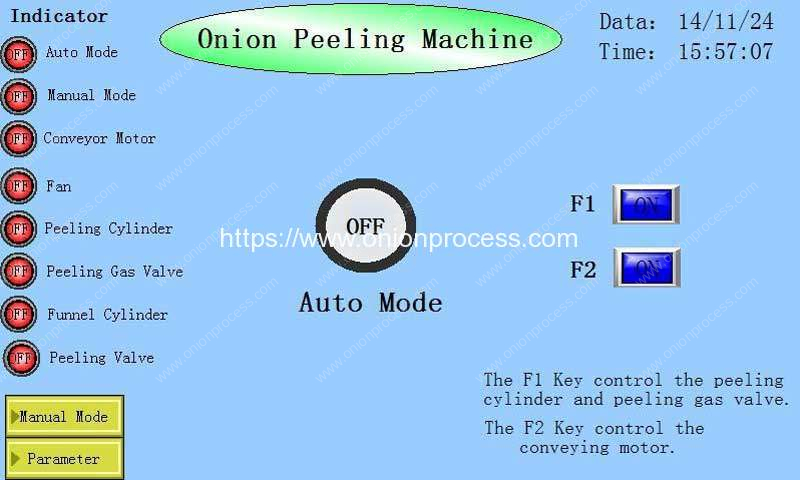

4. Equipment run: After completing step 3, click “Start” on the “Auto Mode” page of the touch screen (Figure 3), and the device enters the automatic running state.

Note: This mode is activated only once the system is powered off or click on “Start” again on the touch screen, and will not affect its operating status due to external “emergency stop” switch and “start” button action.

Add “Function Key” button, you can choose according to the use of onions or do not use “skin function”

5.“Auto Mode”function description:

“F1”:initial state is“On”,if changing could stop the peeling function.

“F2”:initial state is“On”,if changing could stop motor and fan,but the machine still stay in“Auto Mode”state.

6. Device boot sequence:

①Open the air compressor, the pressure adjustment 0.8Mpa ~ 1.0Mpa; the ball valve (Figure 1) open.

②Follow steps 3 and 4, start the “automatic mode”, empty machine running 3 to 5 minutes;

③Observe the equipment without a fault, pour the onion to work.

Company Profile

Adhering to the principle of managing scientifically and honesty and credit,our factory has passed ISO9001-2000 quality system certification. Now, Our factory can provide onion dry cleaning machine, onion water washing machine, onion mesh bag packing machine, onion peeling machine, onion root cutting machine, onion cutting machine, onion dryer machine, onion powder production line, onion powder bottle filling sealing machine.

Our onion processing products have passed with CE,ISO and SGS Certificates and has been widely sold all over the world.